The Ultimate Guide To Premier Aluminum Llc

The Ultimate Guide To Premier Aluminum Llc

Blog Article

Premier Aluminum Llc - Questions

Table of ContentsThe Ultimate Guide To Premier Aluminum LlcThe 7-Second Trick For Premier Aluminum LlcPremier Aluminum Llc - An OverviewThe Only Guide for Premier Aluminum Llc

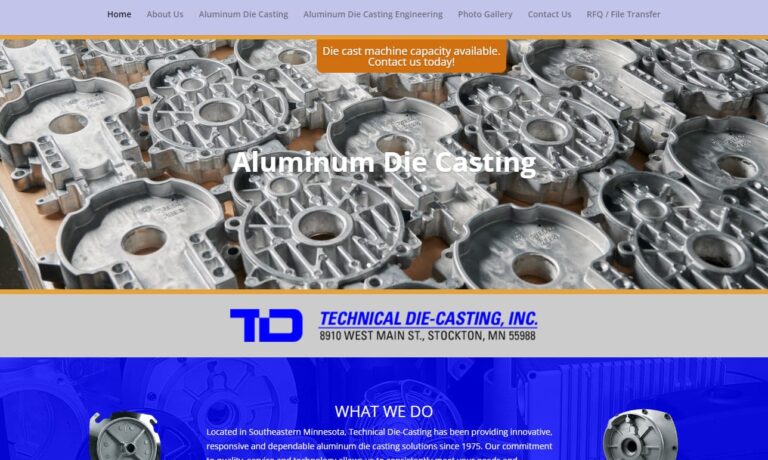

(https://garymartin53403.wixsite.com/my-site-1/post/top-aluminum-casting-company-premier-aluminum-llc)Traditionally, a buyer's main duty was to discover professional and responsive vendors. In many cases, purchasers assumed that any kind of distributor happy to contractually meet the acquisition requirement was qualified. However, making use of inexpensive and unqualified suppliers can create quality problems, and squandered time and money in the long run. To aid you through the process, below are some points to take into consideration when choosing the appropriate metal spreading vendor.

For instance, a company that just utilizes the investment spreading procedure will certainly attempt to offer you on why that procedure is best for your application. Yet what if using the sand casting procedure is best for you and your needs? Rather, search for a provider that uses a range of casting processes so the most effective option for YOU is chosen

If dealing with a solitary resource for all of your casting needs is essential to you, the vendor needs to be varied in its abilities. When combined with various other incorporated capacities, this can help streamline and compress the supply base. When selecting the appropriate spreading provider, mindful factor to consider must be given to high quality, service, and cost.

The smart Trick of Premier Aluminum Llc That Nobody is Discussing

Purchasers significantly choose casting suppliers that have machining abilities. If the spreading vendor finds a problem throughout machining, the issue is fixed faster with no conflict over whose fault it is.

What do you require from your spreading supplier? Are you looking for a person to just supply a metal element to your doorstep or do you require a lot more?

Some foundries are restricted or specialized. Make sure the supplier can meet all your material or alloy demands to eliminate the requirement for numerous providers.

The Of Premier Aluminum Llc

Study the vendor's internet site. Talk to a sales associate or service partner.

Light weight aluminum is likewise light-weight and has great corrosion resistance, making it suitable for applications where weight and longevity are vital elements. Furthermore, light weight aluminum spreading is a cost-efficient approach of manufacturing, as it calls for less energy and resources than other methods. Iron spreading, on the other hand, includes pouring liquified iron into a mold to produce a desired shape.

Some Of Premier Aluminum Llc

Iron spreading is additionally able to stand up to heats, making it ideal for use in applications such as engine components and commercial equipment. Iron spreading can be a lot more costly than aluminum casting due to the greater cost of raw products and the power needed to thaw the iron. When determining in between light weight aluminum spreading and iron spreading, it is necessary to take into consideration the certain needs of the application.

In final thought, both light weight aluminum casting and iron casting have their own special advantages and drawbacks. There are three sub-processes that fall under the classification of die casting: gravity pass away spreading (or irreversible mold casting), low-pressure die spreading and high-pressure die spreading. To get to the ended up item, there are 3 primary alloys utilized as die spreading product to choose from: zinc, light weight aluminum and magnesium. Report this page